Technology is in our side

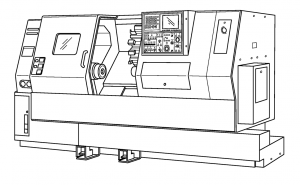

CNC SYSTEMS

GILDEMEISTER CTX400

Specifications:

Number of driven toolspositions 12 pos.

turret (x-stations) 12

rapid traverse Z-axis 15 m/min

rapid traverse X-axis 10 m/min

drive capacity – spindle motor 22 kW

turning speeds 25 – 5.000 U/min

chucking diameter 200 mm

spindle bore 72 mm

bearing diameter 100 mm

spindle nose 140 h5

travel -z axis 640 mm

travel -x axis 212 mm

swing diameter over slide rest 290 mm

swing diameter max. over bed cover 500 mm

control EPL 2

turning length 640 mm

turning diameter 290 mm

MACHINING CENTERS

FANUC ROBODRILL αT21iD

Spindle Speed Max. 20000 rpm

Rapid Travers X, Y,Z 54 mmin

X 500 mm

Y 400 mm

Z 330 mm

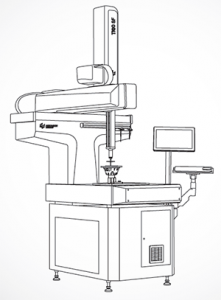

Sistemas de Medición

Centro de Medición de Coordenadas

Centro de Medición de Coordenadas

TIGO SF

In production we aim at a constant flow from milling, drilling, threading, and grinding, all the way to final inspection.

TIGO SF is the most accurate measurement tool to include quality assurance seamlessly. Thanks to its features it is absolutely robust against all the challenges which coordinate measuring machines (CMMs) are faced with on the shop floor.